| Application | Strengthening Foundation Piles Under An Existing Building |

|---|---|

| Location | Turku, Finland |

| Hammer | DFS45 Dual Fluid Drilling System |

| Bit | DFS |

| Hole Size | 6-3/4 inches (170 mm) |

| Depth or Length | 132-165 feet (40-50 m) |

| Formation | Wood, Gravel, Sand, Clay, Granite |

| Rig Type | Custom made Technodrill |

Description

Numa has developed a new and exciting drilling method using a dual fluid process that was utilized on a project in Turku, Finland. The project, one of many contracted to Tekra, required the strengthening of old piles that supported the foundation of an eight story building in Kerttuli’s Square. Located approximately 1640 feet (500 m) from the Aura River, the building was constructed during the 1960’s and had an additional story added to it in the late 1970’s. The strengthening of the piles became necessary when the original wooden piles began to sink due to the tremendous weight they have to support.

Numa has developed a new and exciting drilling method using a dual fluid process that was utilized on a project in Turku, Finland. The project, one of many contracted to Tekra, required the strengthening of old piles that supported the foundation of an eight story building in Kerttuli’s Square. Located approximately 1640 feet (500 m) from the Aura River, the building was constructed during the 1960’s and had an additional story added to it in the late 1970’s. The strengthening of the piles became necessary when the original wooden piles began to sink due to the tremendous weight they have to support.

The project called for drilling 115 5-1/2″ (140 mm) OD piles through the basement floor into bedrock in order to shore-up the sinking building. Each of these piles needed to carry a 60 ton load and was grouted in position after the rock socket was completed. Normal drilling equipment was strictly forbidden on the project because the drill site was located in the basement of an existing building. The contractors feared that using normal drilling methods that use air to flush the hole could cause the hole to blowout or washout and potentially put the stability of the building at risk. To tackle this difficult assignment, Tekra sub-contracted Pirkanmaan Porakaivo Oy who consulted Nordic Drilling Systems regarding Numa’s Dual Fluid Drilling System.

The project called for drilling 115 5-1/2″ (140 mm) OD piles through the basement floor into bedrock in order to shore-up the sinking building. Each of these piles needed to carry a 60 ton load and was grouted in position after the rock socket was completed. Normal drilling equipment was strictly forbidden on the project because the drill site was located in the basement of an existing building. The contractors feared that using normal drilling methods that use air to flush the hole could cause the hole to blowout or washout and potentially put the stability of the building at risk. To tackle this difficult assignment, Tekra sub-contracted Pirkanmaan Porakaivo Oy who consulted Nordic Drilling Systems regarding Numa’s Dual Fluid Drilling System.

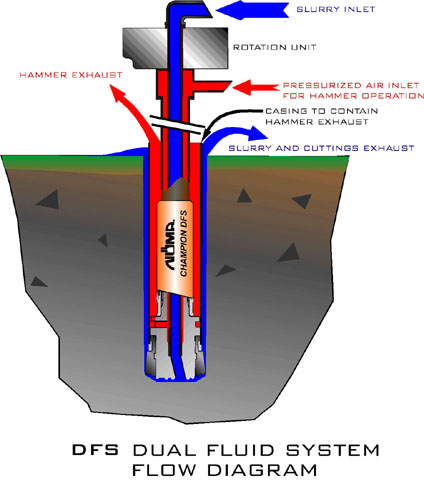

The Dual Fluid Drilling System consists of a special down hole hammer that uses fluid or slurry to clean the hole. Fluid is pumped down the center tube and out the bottom of the drill bit. The pressure of the fluid being pumped down the drill string cleans the bit face and forces all the cuttings up the annulus and outside the casing. This acts to seal off the hole and to prevent any blowouts while drilling. The air that is used to operate the hammer is sent down an air inlet and goes through the hammer to cycle the piston. The air is then exhausted back up through the space located between the hammer and the inside of the casing. This new dual fluid method offers many benefits including the ability to drill perfectly straight holes, faster penetration rates in rock formations, no building damage resulting from vibration, installation of longer drill pipes than with drifters in a confined area, immediate full bearing capacity and immediate grouting is possible. The system has been well received in the construction industry because it provides the ability to continuously drill holes in close proximity to each other, which has never been possible with other drilling methods. With Numa’s Dual Fluid Drilling System, holes can be drilled side-by-side because there is virtually no risk of hole collapse and grouting can follow immediately behind to dramatically save time and money.

The Dual Fluid Drilling System consists of a special down hole hammer that uses fluid or slurry to clean the hole. Fluid is pumped down the center tube and out the bottom of the drill bit. The pressure of the fluid being pumped down the drill string cleans the bit face and forces all the cuttings up the annulus and outside the casing. This acts to seal off the hole and to prevent any blowouts while drilling. The air that is used to operate the hammer is sent down an air inlet and goes through the hammer to cycle the piston. The air is then exhausted back up through the space located between the hammer and the inside of the casing. This new dual fluid method offers many benefits including the ability to drill perfectly straight holes, faster penetration rates in rock formations, no building damage resulting from vibration, installation of longer drill pipes than with drifters in a confined area, immediate full bearing capacity and immediate grouting is possible. The system has been well received in the construction industry because it provides the ability to continuously drill holes in close proximity to each other, which has never been possible with other drilling methods. With Numa’s Dual Fluid Drilling System, holes can be drilled side-by-side because there is virtually no risk of hole collapse and grouting can follow immediately behind to dramatically save time and money.

In Kerttuli’s Square, Pirkanmaan Porakaivo Oy used Numa’s Dual Fluid 140 Drilling System including the Numa DFS45 down hole hammer to drill 6-3/4″ (170 mm) diameter holes while simultaneously installing 5-1/2″ (140 mm) OD casing. All drilling was conducted by a specially designed Technodrill rig that supplied 162 psi (11 bar) and 400 cfm (189 l/sec) of air to the DFS hammer in order to drill approximately 50 feet (15 m) into bedrock. Fluid was pumped down the hole using an on-board Dynaset hydraulic water pump at a variable rate between 10 to 40 gallons (38 – 151 l) of fluid per minute at pressures between 147 to 735 psi (10 – 50 bar).

In Kerttuli’s Square, Pirkanmaan Porakaivo Oy used Numa’s Dual Fluid 140 Drilling System including the Numa DFS45 down hole hammer to drill 6-3/4″ (170 mm) diameter holes while simultaneously installing 5-1/2″ (140 mm) OD casing. All drilling was conducted by a specially designed Technodrill rig that supplied 162 psi (11 bar) and 400 cfm (189 l/sec) of air to the DFS hammer in order to drill approximately 50 feet (15 m) into bedrock. Fluid was pumped down the hole using an on-board Dynaset hydraulic water pump at a variable rate between 10 to 40 gallons (38 – 151 l) of fluid per minute at pressures between 147 to 735 psi (10 – 50 bar).

The project required the dual fluid system to drill through old wooden piles in order to install new steel casing that was grouted and served to strengthen the foundation of the building. Drilling through wood in many instances could prove difficult for many drilling methods because wood is very elastic and  does not fracture easily like rock. However, the dual fluid drill bits are specially designed to penetrate wood and clay but still drill efficiently through gravel, boulders and solid rock. The formations at Kertulli’s Square consisted of clay, wet sand and gravel that provided little resistance for the DFS. The penetration rate varied from 164 feet (50 m) per an hour in soft formation to 16 feet (5 m) in an hour in the granite bedrock.

does not fracture easily like rock. However, the dual fluid drill bits are specially designed to penetrate wood and clay but still drill efficiently through gravel, boulders and solid rock. The formations at Kertulli’s Square consisted of clay, wet sand and gravel that provided little resistance for the DFS. The penetration rate varied from 164 feet (50 m) per an hour in soft formation to 16 feet (5 m) in an hour in the granite bedrock.

The conditions surrounding this project in Finland deemed that many traditional styles of drilling could not be used. It was Numa’s cutting edge approach that provided the necessary means to successfully drill through existing wood piles in the building’s basement without incidence of hole collapse or blowout. Utilizing Numa’s specially designed Dual Fluid Drilling System, the contractor was able to complete the project in an efficient, cost-effective and safe manner.