| Application | Drilling Landslide Protection Piles |

|---|---|

| Location | Kurobe Dam, Japan |

| Hammer | Champion 180 |

| Bit | Conventional |

| Hole Size | 20 inches (508 mm) |

| Depth or Length | Up to 62 feet (19 meters) deep |

| Formation | Granodiorite |

| Rig Type | Tone LFM1500 Skid Mount Electric Drive |

Description

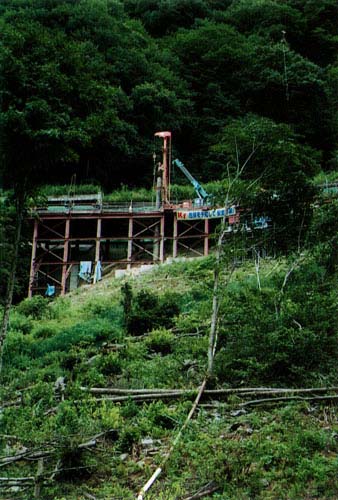

Piling for landslide prevention is an important under-reamer application in many of the mountainous regions of Japan. The contractors are invariably faced with difficult site conditions and often have to build temporary platforms for the drilling rigs in order to complete their jobs. These applications necessitate drill rigs and down the hole hammers that are versatile, as well as powerful and efficient.

Piling for landslide prevention is an important under-reamer application in many of the mountainous regions of Japan. The contractors are invariably faced with difficult site conditions and often have to build temporary platforms for the drilling rigs in order to complete their jobs. These applications necessitate drill rigs and down the hole hammers that are versatile, as well as powerful and efficient.

The Kurobe Dam is located in a very picturesque, unspoiled National Park that is a popular tourist area. When the dam required extensions to be constructed, the water level of the Kurobe Valley Dam would rise very close to a tourist railway line that  traverses an extremely steep slope. In order to insure the safety of the visitors to the park, it was necessary to stabilize the slope immediately below the railway line by drilling landslide prevention piles.

traverses an extremely steep slope. In order to insure the safety of the visitors to the park, it was necessary to stabilize the slope immediately below the railway line by drilling landslide prevention piles.

In undertaking this project, contracting company Toyo Boring Company was faced with even more difficult conditions. Since there was no access road available, access to the site was made possible by constructing an overhead cableway with a 3-ton hoist. All materials and equipment had to be lifted 164 feet (50 m) from the valley floor to the drilling site. This lifting procedure had to be used not only for the drilling equipment, but also for the steel work for the drilling platform, power generating sets, welding rigs, tubular piles and grouting equipment. In fact, the only equipment that was not lifted to the site were the air compressors (two Airman PDSG750S 13bar – 1500 CFM at 125 PSI) that were located on the valley floor with the air being piped to the drilling rigs.

The Kurobe Dam Landslide Protection Project called for 28 piles to be installed up to 62 feet (19 m) deep. Initial drilling of the piles was conducted with an underreaming bit driving 22 inch (559 mm) casing through overburden ground conditions. When they reached hard rock, Toyo Boring used a new, more powerful Numa C180 (Tone NDH-400) hammer and 20 inch (508 mm) bit to socket the piles into bedrock. The air pressure was limited to 125 psi (8.7 kg/cm2) and a Tone air cushioned shock absorber was used to minimize the vibrations on the temporary drilling platform.

The Kurobe Dam Landslide Protection Project called for 28 piles to be installed up to 62 feet (19 m) deep. Initial drilling of the piles was conducted with an underreaming bit driving 22 inch (559 mm) casing through overburden ground conditions. When they reached hard rock, Toyo Boring used a new, more powerful Numa C180 (Tone NDH-400) hammer and 20 inch (508 mm) bit to socket the piles into bedrock. The air pressure was limited to 125 psi (8.7 kg/cm2) and a Tone air cushioned shock absorber was used to minimize the vibrations on the temporary drilling platform.

The success of this project is an example of the cooperative agreement between Numa and Tone Corporation to provide performance-driven drilling products and underreamer bits throughout Japan. As a leading manufacturer of drilling rigs and soil excavation machinery in Japan, Tone was determined to upgrade their DTH hammer range with a product line that would live up to their own high quality under-reamer  standards. After a thorough search and in-depth research, Tone became the exclusive distributor of Numa DTH hammers throughout Japan under an OEM agreement that allows them to market all Numa hammers as Tone NDH hammers. In addition to providing DTH hammers, Tone has also developed a unique design of underreamer bits that are well matched to the Numa hammers and are ideal for overburden drilling applications around the world.

standards. After a thorough search and in-depth research, Tone became the exclusive distributor of Numa DTH hammers throughout Japan under an OEM agreement that allows them to market all Numa hammers as Tone NDH hammers. In addition to providing DTH hammers, Tone has also developed a unique design of underreamer bits that are well matched to the Numa hammers and are ideal for overburden drilling applications around the world.

The Kurobe Dam Landslide Prevention Project provided many obstacles in the form of safety and site access that are not seen everyday in the drilling industry. However, the project was successfully completed quickly and easily due to the versatility of the equipment manufactured and supplied by Numa and Tone. But then again, that’s what you expect from these two leading companies.