| Application | Gas Pipeline Tunneling |

|---|---|

| Location | Maine, Northeastern USA |

| Hammer | Numa 180 and 240 Hammers |

| Bit | Impact Ring Bit System® |

| Hole Size | 32 and 30 inches (813 & 762 mm) |

| Depth or Length | Varying from 60 to 400 feet (18 - 122 m) |

| Formation | Running sands, clay, boulders & solid granite |

| Rig Type | American Auger Model 60-1200 |

Description

In order to supply a larger volume of natural gas to the New England region of the United States, a 1.2 billion dollar Maritimes & Northeast Pipeline, L.L.C. project is nearing completion to install a major natural gas pipeline that extends from the Canadian Maritimes to Massachusetts in the United States. Upon completion, the pipeline will be placed in service and natural gas will flow from Canada.

In order to supply a larger volume of natural gas to the New England region of the United States, a 1.2 billion dollar Maritimes & Northeast Pipeline, L.L.C. project is nearing completion to install a major natural gas pipeline that extends from the Canadian Maritimes to Massachusetts in the United States. Upon completion, the pipeline will be placed in service and natural gas will flow from Canada.

Sheehan Pipeline Construction Company of Tulsa, Oklahoma was awarded Spread 1 of the Maritimes project that consisted of laying 63 miles (101 km) of 24″ (610 mm) O.D. pipeline from Westbrook to Windsor, Maine. Part of Sheehan’s work included horizontally boring underneath major roadways (Interstate Highways I-495 and I-95, etc.), railways and other obstacles.

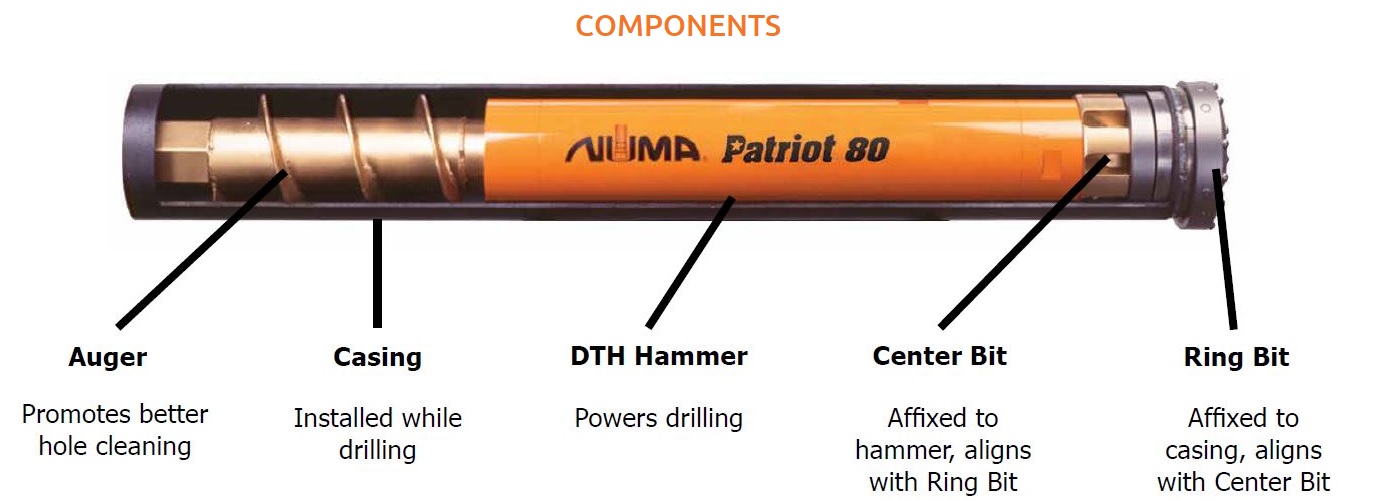

Sheehan’s portion of the project began in May of 1999 and called for over 30 rock bores to be completed in varying lengths from 60 to 400 feet (18 – 122 m). Due to extremely hard rock and boulders that are indigenous to the region, Sheehan realized conventional horizontal boring equipment would not be sufficient to bore the required tunnels. Sheehan hired horizontal rock drilling contractor, Western Utilities, who offered an innovative way to efficiently drill in hard rock using Numa down hole hammers and a two piece ring bit system specially engineered for tunneling applications. The bit system consists of a unique two-piece design, which incorporates a center and ring bit combination. The hammer and center bit are inserted through the casing to align with the ring bit at the end of the casing. While drilling, the two bits work in unison to drill a hole, which allows installation of the casing.

Sheehan’s portion of the project began in May of 1999 and called for over 30 rock bores to be completed in varying lengths from 60 to 400 feet (18 – 122 m). Due to extremely hard rock and boulders that are indigenous to the region, Sheehan realized conventional horizontal boring equipment would not be sufficient to bore the required tunnels. Sheehan hired horizontal rock drilling contractor, Western Utilities, who offered an innovative way to efficiently drill in hard rock using Numa down hole hammers and a two piece ring bit system specially engineered for tunneling applications. The bit system consists of a unique two-piece design, which incorporates a center and ring bit combination. The hammer and center bit are inserted through the casing to align with the ring bit at the end of the casing. While drilling, the two bits work in unison to drill a hole, which allows installation of the casing.

To install the casing for the Maritimes & Northeast Pipeline Project, Sheehan utilized Numa’s Numa 240 and 180 down hole hammers with 32″ and 30″ (813 & 762 mm) two piece ring bit systems. The hammers and bits were powered by an American Auger Model 60-1200 boring rig with three 1300 cfm / 150 psi (614 l/sec / 10.2 bar) air compressors supplied 3900 cfm (1840 l/sec) at 150 psi (10.2 bar). The drilling system also included ribbed over hammers stabilizers to maintain alignment and a flighted drill stem to assist in removing cuttings from the casing.

To install the casing for the Maritimes & Northeast Pipeline Project, Sheehan utilized Numa’s Numa 240 and 180 down hole hammers with 32″ and 30″ (813 & 762 mm) two piece ring bit systems. The hammers and bits were powered by an American Auger Model 60-1200 boring rig with three 1300 cfm / 150 psi (614 l/sec / 10.2 bar) air compressors supplied 3900 cfm (1840 l/sec) at 150 psi (10.2 bar). The drilling system also included ribbed over hammers stabilizers to maintain alignment and a flighted drill stem to assist in removing cuttings from the casing.

For most drilling applications on this project, the boring rig was set up on one side of the highway. Laying horizontally in the rig, the hammer and two piece ring bit system tunnel through rock while the rig simultaneously installs a temporary .500″ (13mm) wall steel casing under the highway. After the hammer and bit exit the rock formation on the other side of the highway, the ring bit is removed from the end of the casing and the hammer and center bit are pulled back through the installed pipe. Then a concrete coated steel carrier pipe is pulled inside the casing and the hammer, center and ring bit are ready to be used on the next rock tunneling location.

For most drilling applications on this project, the boring rig was set up on one side of the highway. Laying horizontally in the rig, the hammer and two piece ring bit system tunnel through rock while the rig simultaneously installs a temporary .500″ (13mm) wall steel casing under the highway. After the hammer and bit exit the rock formation on the other side of the highway, the ring bit is removed from the end of the casing and the hammer and center bit are pulled back through the installed pipe. Then a concrete coated steel carrier pipe is pulled inside the casing and the hammer, center and ring bit are ready to be used on the next rock tunneling location.

In such difficult conditions, conventional horizontal boring equipment could never have completed the tunnels in the allotted time period. It was the combination of Numa’s advanced horizontal drilling products and Western Utilities drilling expertise, that gave Sheehan the ability to horizontally drill through hard rock at rates up to 20 feet (6 m) per hour. Unheard of penetration rates like these are sure to change the tunneling industry forever.