| Application | Drilling for structural and soldier piles |

|---|---|

| Location | Melbourne, Australia |

| Hammer | Champion 240 |

| Bit | Conventional |

| Hole Size | 34 inches (864 mm) |

| Depth or Length | 17 feet (5 meters) deep |

| Formation | Basalt Cap, Silt, Clay, Gravel, Sand, Mudstone |

| Rig Type | Frankipile Atlas Crane and Soilmec RT 3S Kelly Module |

Description

The Quay West Project involved the construction of a new apartment tower in downtown Melbourne, Australia that called for drilling 34 inch (864 mm) diameter holes an average of 17 feet (5 m) through basalt for the installation of 130 foot (40 m) foundation piles. Awarded to Frankipile Australia, the project presented many challenges due to the close proximity to other buildings in the area and difficult ground conditions.

The Quay West Project involved the construction of a new apartment tower in downtown Melbourne, Australia that called for drilling 34 inch (864 mm) diameter holes an average of 17 feet (5 m) through basalt for the installation of 130 foot (40 m) foundation piles. Awarded to Frankipile Australia, the project presented many challenges due to the close proximity to other buildings in the area and difficult ground conditions.

The site was very small and congested, being surrounded by a church, a restaurant complex, an apartment building and the Melbourne Concert Hall. This required a drilling solution that not only could penetrate the basalt quickly, but would also keep noise or vibrations to a minimum. Vibrations were closely monitored and could not exceed 6.0 mm/sec ppv (peak particle velocity).

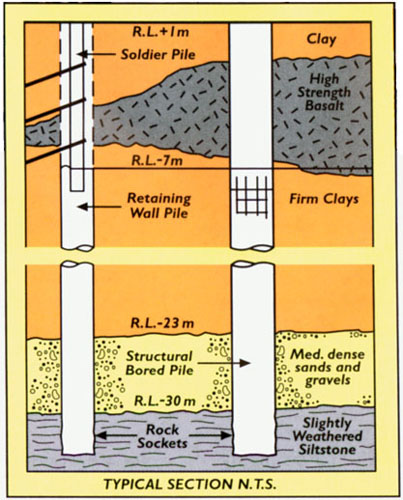

The geography and geology of this area was an interesting array of everything from marine silts to a cap of very competent basalt (29,000 psi / 200 MPa). The basalt cap was located 6 to 20 feet ( 2 – 6 m) below the surface and ranged in quality from extremely weathered to fresh deposits. Below this was 66 feet (20 m) of silt, clay, gravel and sand that were subject to seepage from an adjacent river and artesian water. Finally sockets had to be drilled 3 to 9 feet (1 – 2.8 m) into basement mudstone that was 50 to 90 MPa.

The geography and geology of this area was an interesting array of everything from marine silts to a cap of very competent basalt (29,000 psi / 200 MPa). The basalt cap was located 6 to 20 feet ( 2 – 6 m) below the surface and ranged in quality from extremely weathered to fresh deposits. Below this was 66 feet (20 m) of silt, clay, gravel and sand that were subject to seepage from an adjacent river and artesian water. Finally sockets had to be drilled 3 to 9 feet (1 – 2.8 m) into basement mudstone that was 50 to 90 MPa.

To tackle these conditions, Frankipile utilized new technology and techniques that had never been previously attempted in Australia. Foremost among these innovations was implementing Statnamic testing on the first three piles drilled in order to validate the Frankipile design. One of the major concerns was the drilling of clearance holes through a layer of basalt. This had to be accomplished after boring from the surface, installing the casing and before proceeding into the mudstone bedrock. The solution was the purchase of the largest conventional pneumatic down  the hole hammer in Australia. The hammer, a Numa Champion 240, was mounted on a Frankipile Atlas crane and Soilmec RT 3S kelly module. The hammer was sleeved to 32 inches (813mm) diameter, to provide good clearing of the cuttings from the bit. Despite the many complications the job offered, the Numa C240 hammer drilled at an amazing drilling rate of up to 20 feet (6m per hour).

the hole hammer in Australia. The hammer, a Numa Champion 240, was mounted on a Frankipile Atlas crane and Soilmec RT 3S kelly module. The hammer was sleeved to 32 inches (813mm) diameter, to provide good clearing of the cuttings from the bit. Despite the many complications the job offered, the Numa C240 hammer drilled at an amazing drilling rate of up to 20 feet (6m per hour).

Because of the head room restrictions of the Soilmec Kelly drive, the usual discharge of cuttings to the surface was rejected in favour of a calyx basket. This avoided the need for changing short lengths of sleeved drill pipe. The calyx basket was mounted immediately above the hammer and collected the cuttings below ground level. When the calyx basket (also 32 inches (813 mm) diameter) was full, it was lifted to surface for emptying adjacent to the hole being drilled. The calyx basket was emptied after every 16″ (400mm) of drilling but was raised without the need to remove drill rod sections. Two 1300/175 CFM/PSI (641 l/sec/12 bar) air compressors were used to provide 140 psi (10 bar).

Although the conditions were difficult, Frankipile’s drilling method proved to be a winner. Over the 27 days drilling was conducted, the hammer drilled 60 holes totalling 1050 feet (320 m). The best days production was 66 feet (20 m) of rock in 10.5 hours which included two moves. In addition, the results from the vibration measurements were even more impressive. The results showed that the vibration output of the Champion 240 in these conditions was as low as 0.1 mm/sec ppv to a high of 3.6 mm/sec ppv making it well within the limits and more importantly, left the surrounding community virtually undisturbed.

Although the conditions were difficult, Frankipile’s drilling method proved to be a winner. Over the 27 days drilling was conducted, the hammer drilled 60 holes totalling 1050 feet (320 m). The best days production was 66 feet (20 m) of rock in 10.5 hours which included two moves. In addition, the results from the vibration measurements were even more impressive. The results showed that the vibration output of the Champion 240 in these conditions was as low as 0.1 mm/sec ppv to a high of 3.6 mm/sec ppv making it well within the limits and more importantly, left the surrounding community virtually undisturbed.

Despite the head room limitations of the drilling rig, the performance of the Numa hammer together with good planning and attention to detailed rock drilling parameters, allowed Frankipile to complete the difficult drilling successfully.