For Holes 5¼” to 42” (133 to 1067 mm)

Leading the Industry for Environmentally Challenging or Confined Work Sites

Numa’s Dual Fluid System excels in environmentally challenging or confined sites where contamination risks or nearby infrastructure threaten project safety. Because the system greatly reduces the risk hole collapse, drillers can place holes side-by-side and follow immediately with grouting to save significant time and money.

Numa is the world’s leading drilling technology provider, offering the highest value in products, performance, and service in the entire drilling industry.

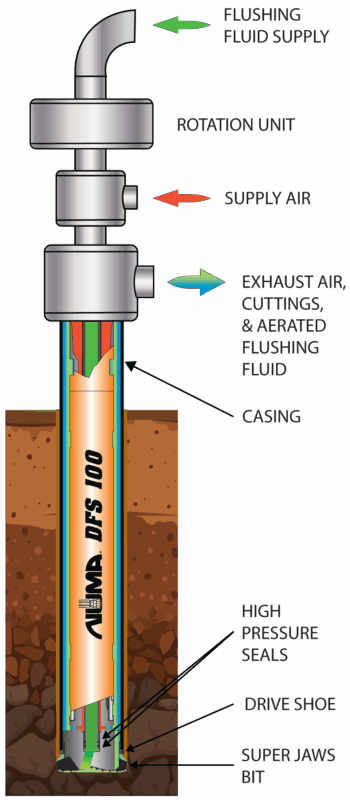

Numa’s Dual Fluid System (DFS) features a specially designed down-hole hammer that uses fluid or slurry to clean the hole. Fluid is pumped down the center tube and out through the bottom of the drill bit. The resulting pressure cleans the bit face and forces all cuttings back up inside the casing, sealing off the hole and preventing blowouts during drilling. Simultaneously, the system sends air down an inlet and through the hammer to cycle the piston. This air then exhausts back up through the space between the hammer and the casing.

Benefits of Numa’s DFS offerings include:

- Drills holes 5¼” to 42” (133 to 1067 mm) in clay, silt, gravel, boulders, and rock.

- Grout through the hammer.

- Eliminates the risk for air over-flushing the hole and creating cavities.

- Does not force pressurized air into the formation damaging surrounding utilities.

- Easy retraction of casing in anchoring applications.

- Clean hole with water, water/bentonite mixture or polymers.

Projects

Kerttuli’s Square Cellar Piling Project – Dual Fluid System

Location: Turku, Finland