| Application | Horizontal Canopy Piles |

|---|---|

| Location | Tung Chung, Hong Kong, China |

| Hammer | Numa Patriot® 185 |

| Bit | Impact Ring Bit System® |

| Hole Size | 33.8583 inches (860 mm) in Diameter |

| Depth or Length | Various lengths of 197 to 230 feet (60 – 70 meters) |

| Formation | Mix of grouted granite rock fill, with silt, clay and bedrock granite |

| Rig Type | Custom BM800LS drilling rigs with Front Steer guiding technology developed by Bohrtec GmbH |

Description

TUNG CHUNG, HONG KONG, CHINA –

The US$3.2 billion Hong Kong Link Road project (HKLR) is a massive construction initiative comprised of sea viaducts, tunnels and at-grade roads. The 7.5 mile (12 km) long HKLR will connect the Hong Kong – Zhuhai – Macao Bridge (HZMB) at the HKSAR boundary with the Hong Kong Boundary Crossing Facilities (HKBCF) situated at the north eastern waters of the Hong Kong International Airport. Upon completion, it will open a direct connection route between Hong Kong, Macao and the Western Pearl River Delta.

The US$3.2 billion Hong Kong Link Road project (HKLR) is a massive construction initiative comprised of sea viaducts, tunnels and at-grade roads. The 7.5 mile (12 km) long HKLR will connect the Hong Kong – Zhuhai – Macao Bridge (HZMB) at the HKSAR boundary with the Hong Kong Boundary Crossing Facilities (HKBCF) situated at the north eastern waters of the Hong Kong International Airport. Upon completion, it will open a direct connection route between Hong Kong, Macao and the Western Pearl River Delta.

The HKLR comprises a 6 mile (9.4 km) viaduct going from the HKSAR boundary to Scenic Hill on the Airport Island, a 0.6 mile (1 km) tunnel section to the reclamation formed along the east coast of the Airport Island and a one mile (1.6 km) long at-grade road section on the reclamation connecting to the HKBCF. The tunnel section of HKLR will pass under Scenic Hill, Airport Road and Airport Railway to minimize the environmental and visual impacts to Tung Chung residents

Intrafor, a subsidiary of VSL International, was selected for construction of a pipe canopy required to provide a temporary support during the tunnel box excavation work. Intrafor specializes in ground engineering and foundation construction works that are technically challenging. The company’s expertise is based  on a long history of proven design and build capability on some of the most complex, varied and demanding projects. Intrafor offers its’ clients a complete package to meet all their geotechnical requirements from preliminary studies and concepts, through to design, construction and ongoing monitoring.

on a long history of proven design and build capability on some of the most complex, varied and demanding projects. Intrafor offers its’ clients a complete package to meet all their geotechnical requirements from preliminary studies and concepts, through to design, construction and ongoing monitoring.

The pipe canopy was a requirement because it allowed for the installation of pipe jacking for two tunnels under the Airport Express Link (AEL), the railway that connects Hong Kong’s International Airport to the city center. With the railway being active, the canopy improved the stability of the ground and minimized settlement, allowing the AEL to continue operations during the construction of the tunnels. The pipes were installed just 40 feet (12 meters) below the track bed so accuracy on the project was critical.

The canopy design called for Intrafor to install 44 steel-casing pipes in two sections. The first section required 20 pipes and the second section 24 pipes. The ground conditions in both sections were varied with a mixed formation profile of stiff boulders, hard granite rock, silt and clay. To efficiently drill in these conditions both sections were completed using Front-Steer drilling rigs and down-the-hole (DTH) percussion hammers and bits.

As specified by Intrafor, two tailor-made BM800LS drilling rigs each combined with Front Steer guiding technology developed by Bohrtec GmbH were used for the horizontal drilling project. The Front Steer system was selected because it is fitted with a sophisticated guidance system that constantly keeps and monitors the drilling alignment, ensuring high accuracy for the pipe installation. Accuracy of ± 75 mm vertical and ± 100 mm horizontal was specified due to the close proximity of the holes being drilled. Bohrtec was chosen due to their 30+ years of experience designing and manufacturing machines for horizontal directional drilling. Their boring machines have clearly demonstrated superiority with regard to technical, economical and ecological aspects.

As specified by Intrafor, two tailor-made BM800LS drilling rigs each combined with Front Steer guiding technology developed by Bohrtec GmbH were used for the horizontal drilling project. The Front Steer system was selected because it is fitted with a sophisticated guidance system that constantly keeps and monitors the drilling alignment, ensuring high accuracy for the pipe installation. Accuracy of ± 75 mm vertical and ± 100 mm horizontal was specified due to the close proximity of the holes being drilled. Bohrtec was chosen due to their 30+ years of experience designing and manufacturing machines for horizontal directional drilling. Their boring machines have clearly demonstrated superiority with regard to technical, economical and ecological aspects.

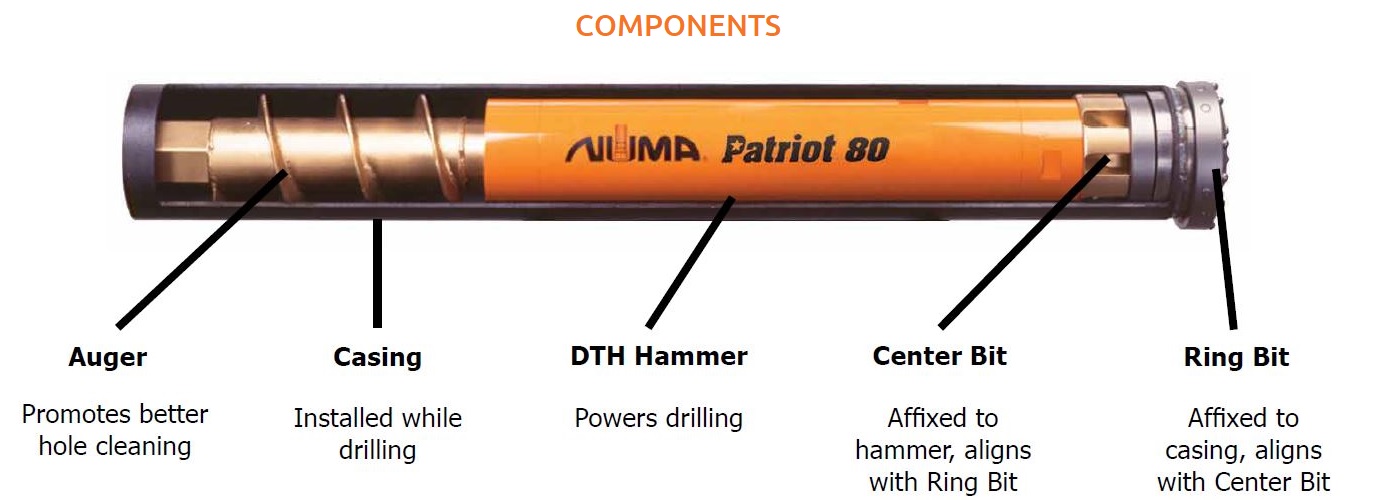

To drill the 44 horizontal holes, Intrafor used Numa Patriot 185 DTH hammers using the Numa Impact Ring Bits®. Numa’s Impact Ring Bit System consists of a unique two-piece design incorporating a center and ring bit combination. On this project, the center bit was attached directly to the DTH hammer used to power the drilling.

The hammer and center bit were concentrically located inside the Front Steer and the ring bit was assembled at the front end after the hammer and center bit were installed. The Front Steer was attached to the casing, and the hammer, ring bit and center bit worked in unison to install the piping while drilling. Upon completion of the hole, the center bit and drill string were pulled back out leaving the pipe installed. The ring bit was fully recoverable in the horizontal drilling application and was re-used for drilling multiple holes.

The Numa hammers and Impact bits drilled 33.8583 inch (860 mm) diameter holes for installation of 32.0079 inch (813 mm) OD pipe with 16 mm wall thickness. Single pipe lengths of 39 feet (12 meter) with fully welded joints were used to a total length of between 197 to 230 feet (60 – 70 meters) long. The ground formation consisted of grouted granite rock fill and bedrock granite up to 250 MPa. To further complicate matters, the installation points were in close proximity to existing rail lines so impact to surrounding areas had to be kept to a minimum and accuracy was essential. Despite these challenging ground conditions, the drilling team met the requirements of drilling accuracy of vertical +/- 75 mm and horizontal +/- 100 mm while drilling 13 to 26 feet per hour (4 – 8 meters/hour).

The Numa hammers and Impact bits drilled 33.8583 inch (860 mm) diameter holes for installation of 32.0079 inch (813 mm) OD pipe with 16 mm wall thickness. Single pipe lengths of 39 feet (12 meter) with fully welded joints were used to a total length of between 197 to 230 feet (60 – 70 meters) long. The ground formation consisted of grouted granite rock fill and bedrock granite up to 250 MPa. To further complicate matters, the installation points were in close proximity to existing rail lines so impact to surrounding areas had to be kept to a minimum and accuracy was essential. Despite these challenging ground conditions, the drilling team met the requirements of drilling accuracy of vertical +/- 75 mm and horizontal +/- 100 mm while drilling 13 to 26 feet per hour (4 – 8 meters/hour).

The use of Numa’s Patriot hammers and Impact Ring Bit System provided a great benefit to the drilling project. With Numa’s advanced design, Intrafor was able to realize lower equipment costs, precise drilling accuracy, and high drilling performance in extremely difficult drilling conditions.

For more information on Numa products and services, please email us at info@numahammers.com, call us on 860.923.9551, or visit our website at www.numahammers.com