For Holes 5¼” to 50½” (133 to 1283 mm)

Seamless Performance for Horizontal Boring

Numa’s Impact Ring Bit System® provides outstanding performance for simultaneously drilling and casing in horizontal boring applications using track-mounted boring machines. Used for the installation of tunnels, canopy piles, pipelines, or cable ducts in rock or overburden formations, the system works seamlessly with guidance systems to ensure precise accuracy for casing installation.

Horizontal Boring Products to Meet Your NEeds

Benefits of Impact Ring Bit Systems include:

- Faster penetration due to large bit surface area contacting formation

- Saves money as all components are reusable on multiple projects

- Efficient hole cleaning through large flushing holes and use of an auger

- Exceptional performance when used with rail-mounted boring machines

Numa is the world’s leading drilling technology provider, with the highest value in products, performance and service in the entire drilling industry.

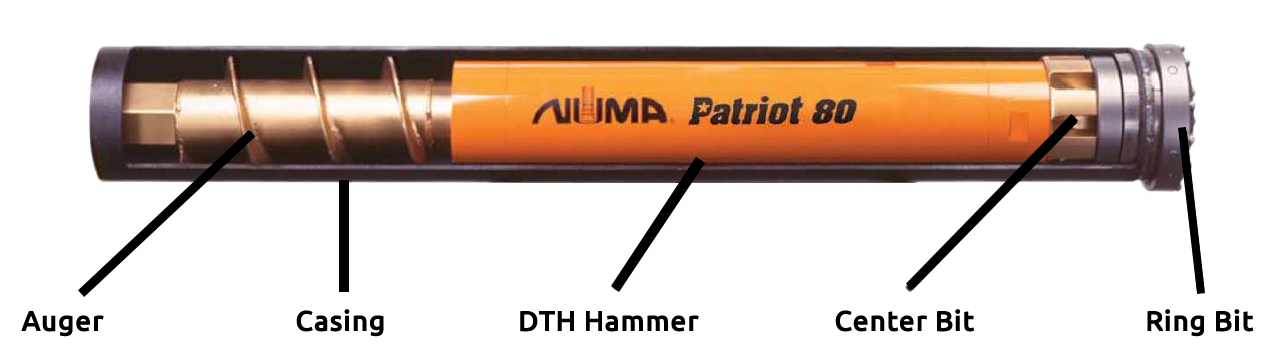

Numa’s Impact Ring Bit System consists of a hammer, auger, and two-piece center/ring bit. To drill, the hammer, auger and center bit are inserted through the casing to align with the ring bit attached to the casing. The hammer powers the drilling while the auger fitted on the backhead of the hammer promotes more efficient cleaning of the hole during drilling. The two bits work in unison to install the casing.

Upon completion of the hole, the center bit and drill string are pulled back for recovery while leaving the casing installed. The ring bit can also be recovered in many horizontal drilling applications and can be re-used for drilling multiple holes. The ability to reuse the full system on multiple holes/projects saves drillers considerable cost.

Impact Ring Bit System

PRODUCTS

Impact Ring Bit System®

Projects

Ireland Gas Pipeline Project Using Impact Ring Bit System

Location: Dublin, Ireland

Pipe Canopy Drilling for Hong Kong Link Road

Location: Tung Chung, Hong Kong, China

Pipeline Expansion Using Impact Ring Bit System

Location: New Hampshire, Eastern USA

Rock Boring Project Using Impact Ring Bit System

Location: British Columbia, Western Canada

Steel Pressure Relief Drain Using Impact Ring Bit System

Location: Shropshire County, United Kingdom

Tuscarora Gas Pipeline Installation Project Using Impact Ring Bit System

Location: Western USAFeatured Video